It is almost unimaginable today, but there was a time when aluminum was more valuable than gold. In mid-19th century France, the elite dined with aluminum cutlery while the less fortunate could only hope to use gold. The reason was simple: aluminum, though abundant in the Earth’s crust, was incredibly difficult to isolate, requiring energy-intensive, experimental methods that rendered it a near-luxury metal. It was only after the independent inventions of the Hall-Héroult process by Charles Hall in the United States and Paul Héroult in France in 1886 that aluminum became industrially viable, heralding the first great democratization of a previously rare metal.

Today, aluminum sits in a very different place. It is the second-most consumed structural metal in the world, essential for industries ranging from aerospace to construction, automotive, and consumer electronics. Yet, despite its abundance, the aluminum industry faces a triple crisis: soaring energy costs, tightening carbon regulations, and the gradual depletion of high-grade bauxite reserves. Smelters now compete with energy-hungry sectors like AI data centers and renewable grids, while CO₂ penalties make traditional aluminum production increasingly untenable. And just as in the past, scarcity still drives value—but now it is scarcity of sustainably produced aluminum.

Sahit Muja said, “Having spent over 30 years in mining, metals technology, and international metals trading, I have witnessed firsthand how industries adapt to scarcity and technological disruption. Aluminum’s current challenges are creating a historic pivot point: the age of magnesium-aluminum alloys”.

Magnesium: The Lightweight Game-Changer

Magnesium, often overshadowed by aluminum and steel, is quietly poised to redefine the future of structural metals. Lighter than aluminum by 33% and far lighter than steel, magnesium enables unparalleled weight reduction without compromising strength. When alloyed with aluminum, it produces materials that are stronger, thinner, more vibration-dampening, and electromagnetically resilient.

This is not mere speculation—these alloys are already industry standards in electric vehicles, aerospace, and high-performance industrial applications, delivering energy efficiency gains, carbon footprint reductions, and unmatched mechanical performance. In short, magnesium-aluminum alloys are the metals of the green industrial revolution.

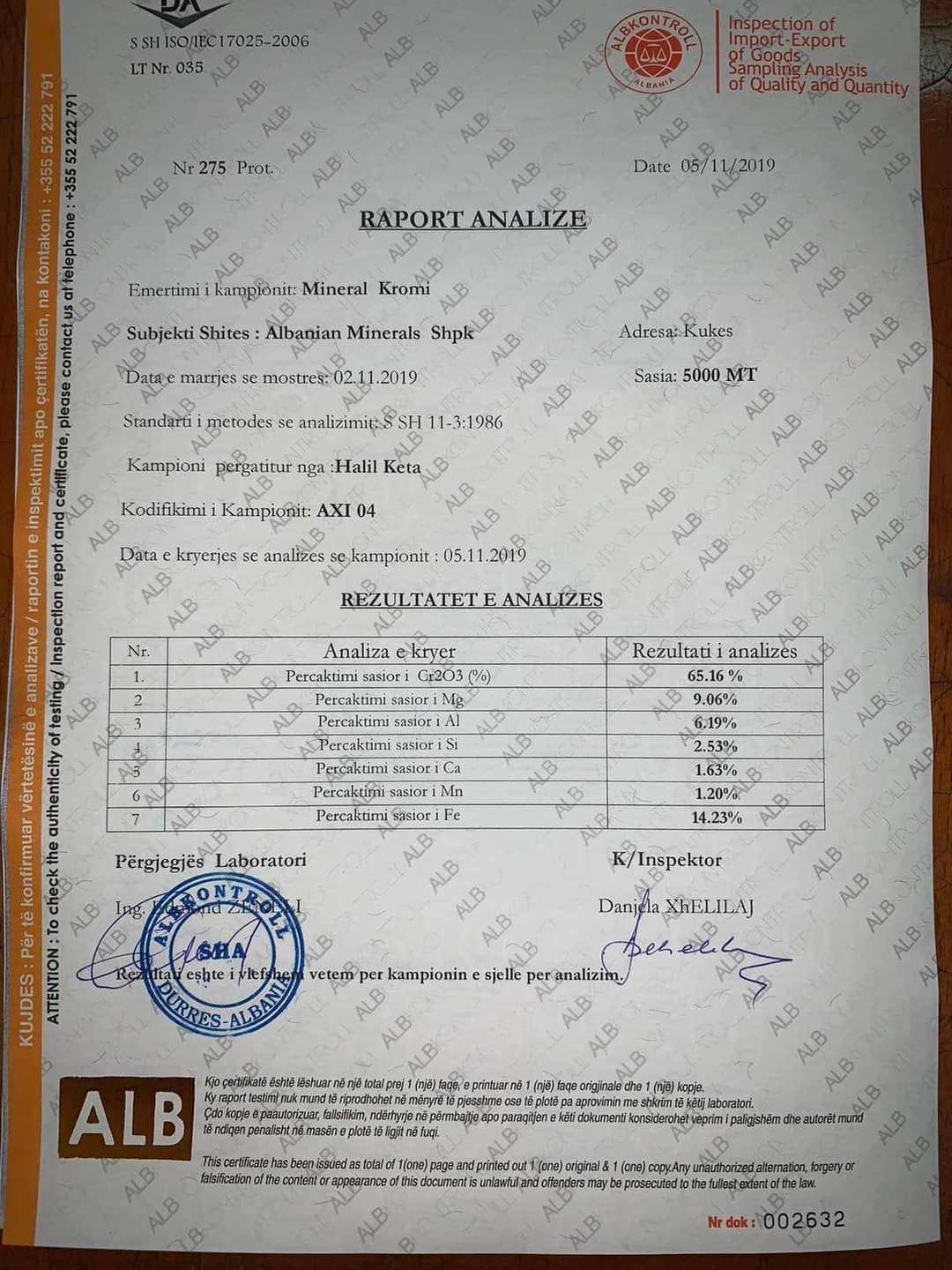

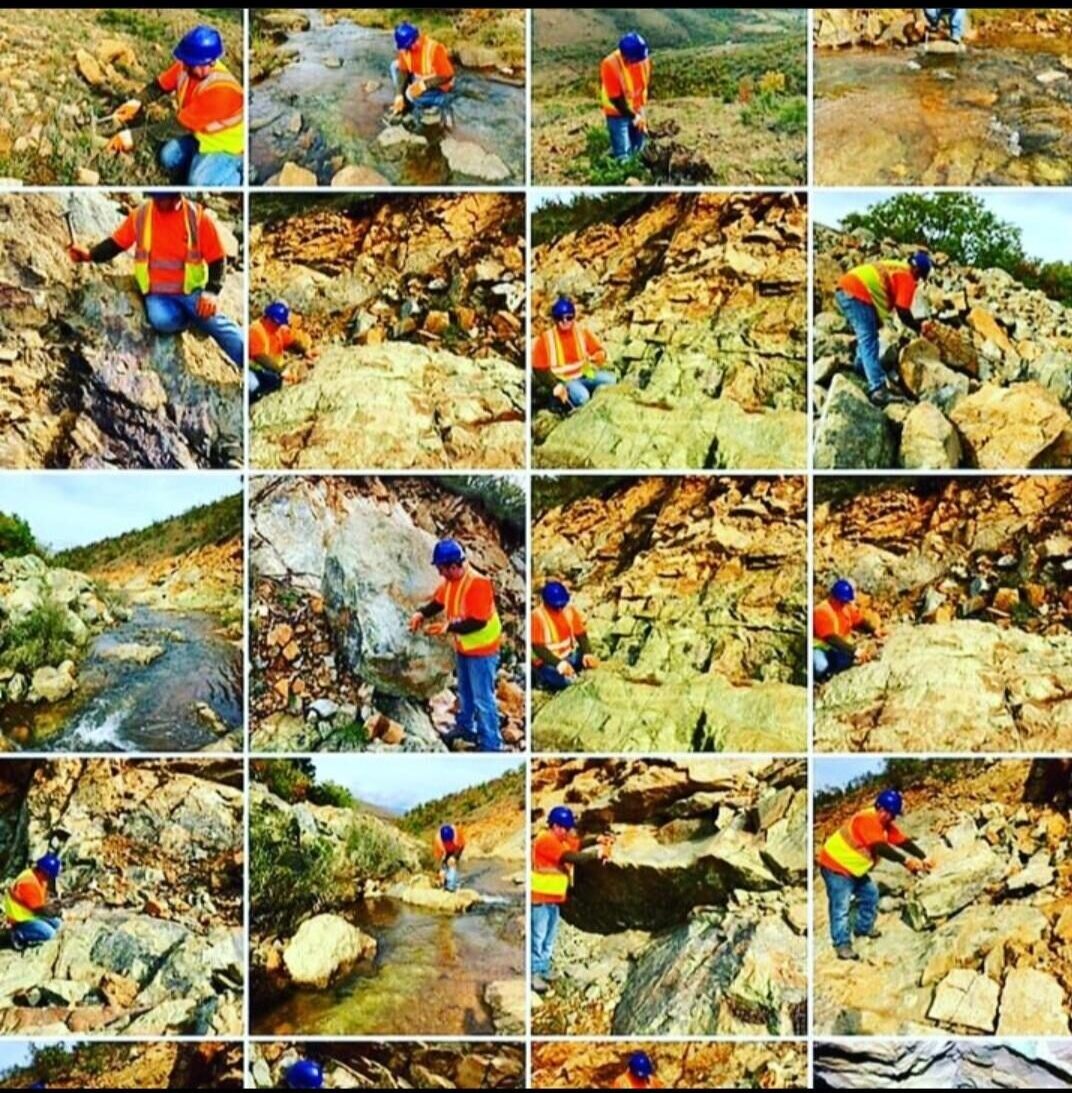

Albanian Mineral: Pioneering the Green Magnesium Era

At the forefront of this transformation is Albanian Mineral, whose CEO, Sahit Muja, has declared the company’s mission to harness the largest high-grade magnesium reserves in the world. Albanian Mineral is not just sitting on a resource; it is actively developing zero-carbon magnesium production technology. This is a breakthrough: magnesium produced entirely from renewable energy, with closed-loop chemical processes that eliminate CO₂ emissions, transforming the way the world thinks about structural metals.

As CEO Sahit Muja emphasizes, “We are not just mining a metal. We are building the foundation for a new, sustainable industrial era. Magnesium is no longer a supporting actor—it is the star of the green economy.”

The Opportunity: A Green Metal Revolution

The potential of magnesium-aluminum alloys goes beyond weight savings. In a world urgently transitioning to clean energy, every kilogram matters: lighter vehicles mean longer EV range, lighter aircraft consume less fuel, and industrial machinery operates more efficiently, all while dramatically reducing material and energy consumption. Magnesium’s versatility extends further: from biodegradable medical implants to next-generation batteries, the metal is poised to touch every critical sector of the economy.

Investors are starting to recognize that we are at the cusp of a sovereign-scale industrial opportunity. Unlike traditional aluminum, which is energy-intensive and carbon-constrained, magnesium—particularly from Albanian Mineral’s ultra-high-grade reserves—offers a scalable, green, and strategic alternative. Pilot projects are already in planning stages, aiming to bring industrial-scale zero-carbon magnesium production online by 2027, positioning the company at the epicenter of the next global metals revolution.

The Magnesium-Aluminum Alloy Advantage

The allure of magnesium-aluminum alloys is multi-dimensional:

Strength-to-weight ratio: Components can be lighter, stronger, and thinner, reducing energy and material costs.

Vibration damping: These alloys offer 10x better damping than pure aluminum, ideal for high-performance transport and industrial machinery.

Electromagnetic shielding: Critical for electric vehicles, renewable energy infrastructure, and electronics.

Carbon reduction: Replacing aluminum with magnesium-aluminum alloys can cut material CO₂ emissions by more than 90%, accelerating corporate and national climate targets.

Every ton of magnesium alloyed with aluminum creates multiple downstream opportunities in automotive, aerospace, energy storage, and construction—truly transforming a raw material into a cornerstone of the green economy.

Europe’s Strategic Advantage

Europe, with its focus on green energy, sustainable transport, and circular economies, is uniquely positioned to capitalize on magnesium’s rise. Albanian Mineral’s reserves offer the continent a sovereign-scale source of high-quality magnesium, reducing dependence on imports and providing a foundation for advanced manufacturing and industrial innovation.

In an era where energy-intensive aluminum production faces growing costs and regulatory pressures, magnesium-aluminum alloys provide a clear path to sustainable, high-performance, and profitable metals. It is not just a material opportunity—it is a strategic, geopolitical, and industrial pivot.

A Vision for the Future

Albanian Mineral’s work is more than mining—it is rewriting the rules of industrial metals. By developing carbon-free magnesium production technology, the company is setting the stage for a new era in alloys, energy-efficient transport, renewable infrastructure, and sustainable industrial growth. The planned 2027 pilot project represents a launchpad for global impact, signaling a future where green metals are not niche or experimental—they are foundational.

As CEO Sahit Muja remarks, “We are building a legacy not measured in tons or revenues, but in the industries we transform, the emissions we prevent, and the new economy we help shape. Magnesium is more than metal—it is a movement.”

The industrial world stands at a crossroads reminiscent of the moment aluminum became cheaper than gold—a time when scarcity, innovation, and vision collided to redefine the possible. Today, magnesium-aluminum alloys represent the next frontier, offering lighter, stronger, and more sustainable materials for a rapidly electrifying and decarbonizing world.

For investors, innovators, and industrial leaders, the message is clear: the green metal revolution has begun, and those who harness magnesium’s potential will shape the next century of global industry. Albanian Mineral is not merely participating in this revolution—it is leading it, proving that foresight, technology, and sustainable thinking can turn a simple metal into a transformative force.

Magnesium is no longer the quiet cousin of aluminum. It is the metal of the future, and Albanian Mineral is writing its first, monumental chapters.